Call: 07971258186

High-Quality, Reliable and Durable Automatic Wire Cutting and Stripping Machines, Brass Hollow Pins, Brass Inserts, and Insert Connectors, etc.

- New Arrivals

- Featured

Techlon India, established in 2022 in Delhi, India, is a major manufacturer, trader, supplier, and importer of precision electrical and

electronic components. Since our inception, we have focused on

delivering high-quality products backed by advanced technology, reliable

processes, and customer-centric service. With a commitment to

innovation and performance, we cater to diverse industries that demand

accuracy, durability, and efficiency.

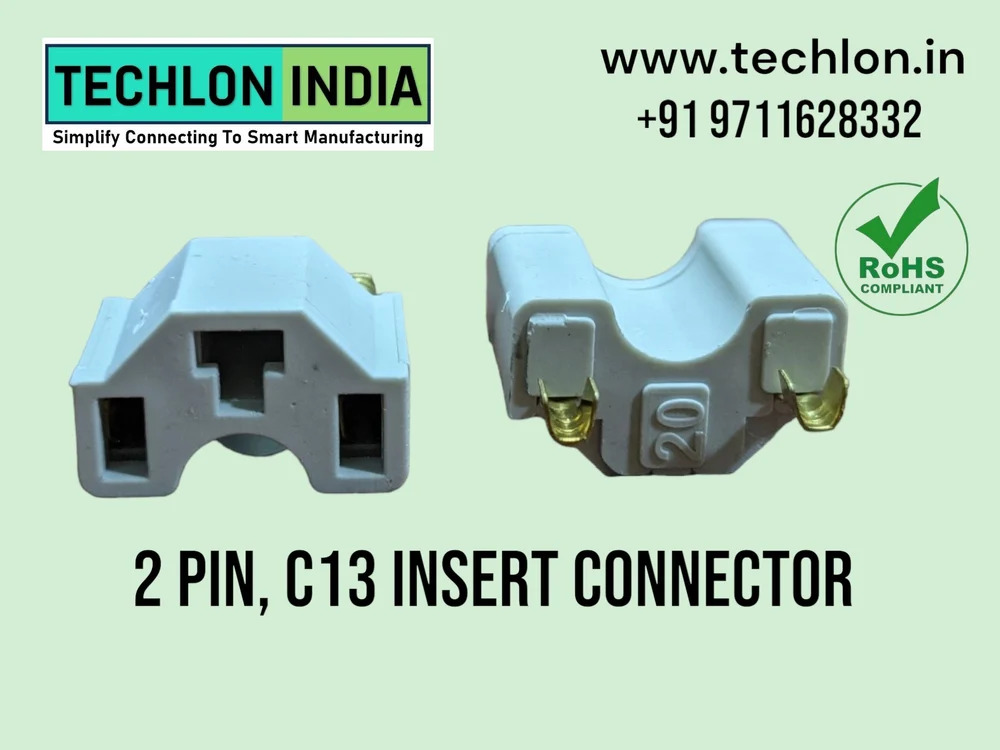

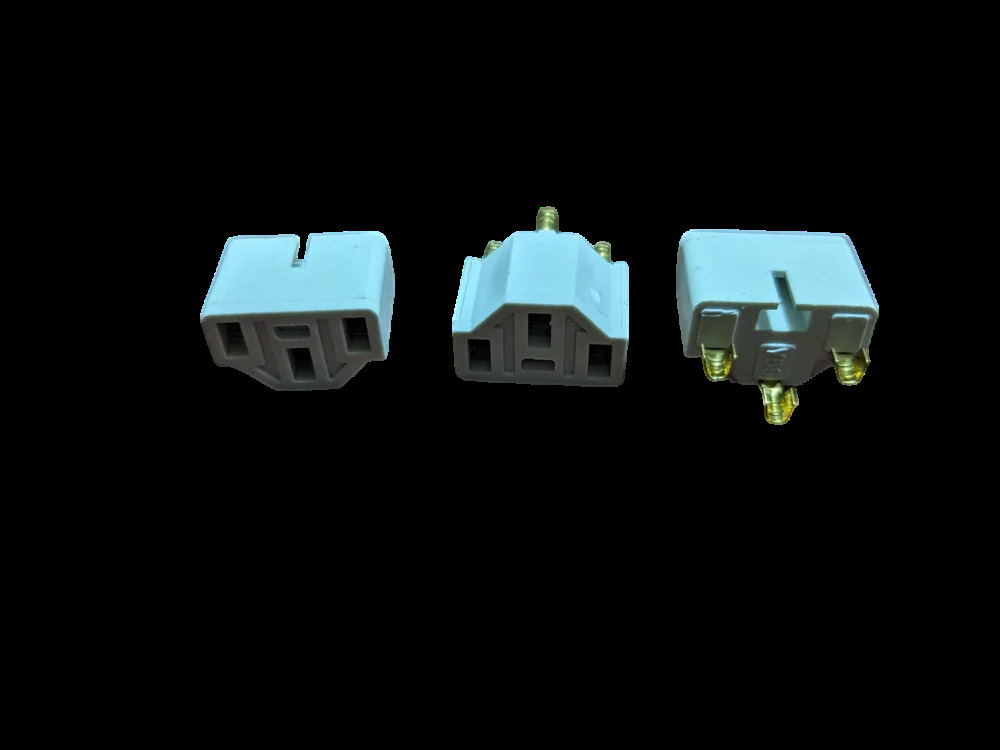

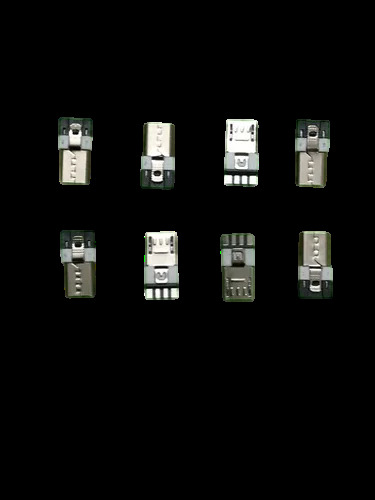

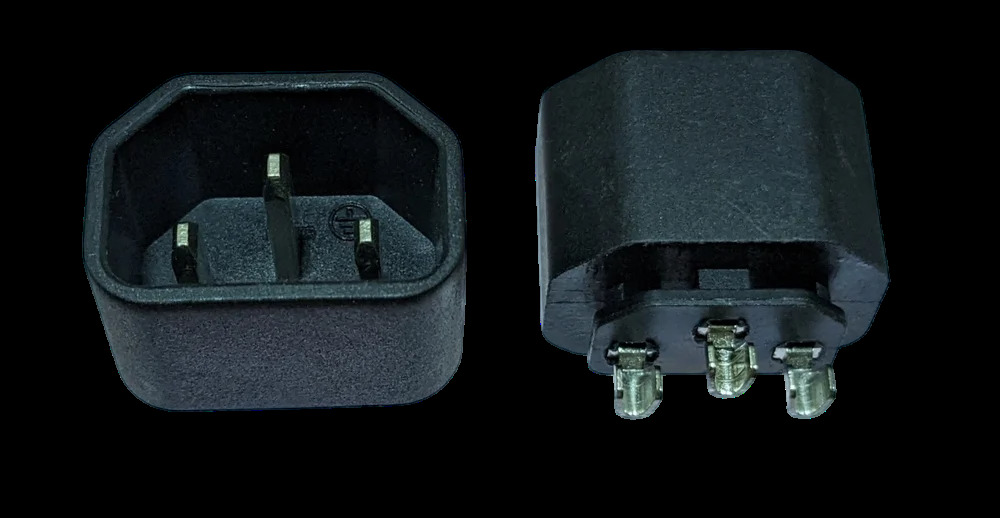

We specialize in offering a robust range of products, including Automatic Wire Cutting and Stripping Machines, Brass Hollow Pins, Brass Inserts, and Insert Connectors. Each product is carefully engineered to meet strict industry standards, ensuring consistent performance in demanding applications. Our automated machinery solutions are designed to improve productivity and precision, while our brass components deliver strength, reliability, and long-term usability.

As both a supplier and an importer, Techlon India bridges global technology with local requirements. Our goal is to provide customers with dependable solutions that enhance their manufacturing capabilities. We continuously expand our product range and upgrade our technologies to align with evolving market needs.

Manufacturing Facilities & Machinery

Techlon India is equipped with modern and well-structured manufacturing facilities designed to support high-precision production. Our unit in Delhi integrates advanced technology, streamlined workflows, and strict quality-control systems to ensure consistent performance in every product we deliver.

Our facility houses a wide range of specialized machines that enhance speed, accuracy, and reliability during production. Key equipment includes:

Our Team

Our team includes qualified engineers, machine operators, quality inspectors, procurement specialists, and customer support executives who work together to ensure smooth operations from production to delivery. Their combined knowledge enables us to develop innovative solutions, maintain strict quality standards, and respond effectively to diverse client requirements. Regular training programs keep our team updated with the latest technologies, industry trends, and safety practices. This continuous learning approach empowers them to operate advanced machinery, handle complex manufacturing processes, and deliver consistent results.

We specialize in offering a robust range of products, including Automatic Wire Cutting and Stripping Machines, Brass Hollow Pins, Brass Inserts, and Insert Connectors. Each product is carefully engineered to meet strict industry standards, ensuring consistent performance in demanding applications. Our automated machinery solutions are designed to improve productivity and precision, while our brass components deliver strength, reliability, and long-term usability.

As both a supplier and an importer, Techlon India bridges global technology with local requirements. Our goal is to provide customers with dependable solutions that enhance their manufacturing capabilities. We continuously expand our product range and upgrade our technologies to align with evolving market needs.

Manufacturing Facilities & Machinery

Techlon India is equipped with modern and well-structured manufacturing facilities designed to support high-precision production. Our unit in Delhi integrates advanced technology, streamlined workflows, and strict quality-control systems to ensure consistent performance in every product we deliver.

Our facility houses a wide range of specialized machines that enhance speed, accuracy, and reliability during production. Key equipment includes:

- Automatic Wire Cutting and Stripping Machines High-efficiency machines capable of precise cutting, stripping, and processing of various wire types, ensuring uniform output at large volumes.

- CNC and Semi-Automatic Turning Machines Used for manufacturing high-precision brass inserts, brass hollow pins, and connector components with tight tolerances.

- Hydraulic and Pneumatic Press Machines Essential for insert molding, connector assembly, and high-accuracy metal shaping.

- Drilling, Tapping, and Threading Machines Ensuring flawless internal and external threading for insert and connector applications.

- Quality Testing Instruments Including micrometers, digital calipers, pull-force testers, and material-testing equipment to maintain industry standards.

Our Team

Our team includes qualified engineers, machine operators, quality inspectors, procurement specialists, and customer support executives who work together to ensure smooth operations from production to delivery. Their combined knowledge enables us to develop innovative solutions, maintain strict quality standards, and respond effectively to diverse client requirements. Regular training programs keep our team updated with the latest technologies, industry trends, and safety practices. This continuous learning approach empowers them to operate advanced machinery, handle complex manufacturing processes, and deliver consistent results.

Back to top

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese